DTG-M02 series 1.5 in3 filter drier

- Home

- Ds dtgm02 r1812

DTG-M02 series 1.5 in3 filter drier

ref. DS-DTGM02-R1812

DTG-M02 series 1.5in3 filter drier are mainly used for light commercial refrigeration applications, with unidirectional flow to absorb moisture and filter out the impurities.

Features

- Stainless steel housing with high-strength

- Housing surface adopts adsorption principle to form a nano-solid film to anti-rust, survives more than 1500 hours of neutral salt spray test.

- Solid filer cores, highly efficient in moisture absorption, filtering impurity.

- Compact design, meeting the strict 150g system limits for flammable refrigerants such as R290.

General Specifications

- Applicable refrigerants: HCFC, HFC, HC, HFO

- Medium temperature: -30℃~+120℃

- Ambient temperature: -30°C~ +55°C

- Max. Operation pressure PS max: 4.83MPa(48,3bar) - 700PSI

- Installation position:

- -Flow direction corresponds to the arrow

- -Preferably installed in liquid line

- Certification: UL/CSA and PED declaration

|

Pos. No. |

Model Designation Legend |

||

|

1 |

Product Code |

Filter Drier Series |

|

|

DTG |

Indicates unidirectional filter drier |

||

|

2 |

Filter Core |

Structure and Material |

|

|

M |

Solid core, 100%3Å desiccant, stainless steel housing |

||

|

3 |

Filter core volume |

[ inch3 ] |

[ cm3 ] |

|

02 |

1.5 |

25 |

|

|

4 |

Connection Size |

Pos. 5 shows "0": Solder [inch] |

|

|

02 |

1/4 |

||

|

03 |

3/8 |

||

|

04 |

1/2 |

||

|

4 |

Connection Size |

Pos. 5 shows "1": Solder [mm] |

|

|

06 |

6 |

||

|

10 |

10 |

||

|

12 |

12 |

||

|

5 |

Pipe Connection |

Type |

|

|

0 |

Solder with inch connections |

||

|

1 * |

Solder with metric connections |

||

|

6 |

Version Number |

Description |

|

|

901 |

Series number |

||

Model Designation Example:

|

Position Number |

According to Model Designation Legend |

|||||

|

1 |

2 |

3 |

4 |

5 |

6 |

|

|

DTG |

M |

02 |

02 |

0 |

901 |

Unidirectional filter drier |

|

DTG |

M |

02 |

02 |

0 |

901 |

Solid filter core with 100% 3Å desiccant, stainless steel housing |

|

DTG |

M |

02 |

02 |

0 |

901 |

1.5 inch3filter core volume |

|

DTG |

M |

02 |

02 |

0 |

901 |

When Pos. 5 is “0”: connection size 1/4” inch |

|

DTG |

M |

02 |

02 |

0 |

901 |

Solder connection inch |

|

DTG |

M |

02 |

02 |

0 |

901 |

Series number |

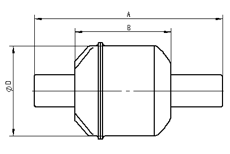

General Characteristics

|

Filter |

Model |

Part number (Industrial pack) |

Solder connection |

Dimensions & weight) |

PED Category |

||||

|

ØD |

B |

A |

Weight |

||||||

|

[inch] |

[mm] |

[mm] |

[mm] |

[mm] |

[g] |

||||

|

DTGM022s |

DTG-M02020-901 |

10230041401 |

1/4 |

- |

42 |

45 |

77 |

95 |

Art. 4.3 |

|

DTGM023s |

DTG-M02030-901 |

10230039601 |

3/8 |

- |

42 |

45 |

77 |

95 |

Art. 4.3 |

|

DTGM024s |

DTG-M02040-901 |

10230041501 |

1/2 |

- |

42 |

45 |

83 |

95 |

Art. 4.3 |

Selection Table

|

Model |

Capacity¹⁾ [kW] |

Moisture Absorption (gram H2O) |

|||||||||||

|

R134a |

R404A |

R290 |

R407C²⁾ |

R410A |

R134a |

R404A |

R407C²⁾ |

R290 |

|||||

|

R507A |

R410A |

||||||||||||

|

R507A |

75°F |

125°F |

75°F |

125°F |

75°F |

125°F |

75°F |

125°F |

|||||

|

23,9°C |

51,7°C |

23,9°C |

51,7°C |

23,9°C |

51,7°C |

23,9°C |

51,7°C |

||||||

|

DTGM022s |

2.33 |

1.64 |

2.56 |

2.36 |

2.36 |

3.2 |

2.8 |

3.5 |

2.9 |

2.7 |

2.5 |

3.0 |

2.2 |

|

DTGM023s |

3.50 |

2.46 |

3.85 |

3.54 |

3.54 |

3.2 |

2.8 |

3.5 |

2.9 |

2.7 |

2.5 |

3.0 |

2.2 |

|

DTGM024s |

4.67 |

3.28 |

5.13 |

4.72 |

4.82 |

3.2 |

2.8 |

3.5 |

2.9 |

2.7 |

2.5 |

3.0 |

2.2 |

Note:

1) the above data is based on clean system at ideal conditions; with impurities, accumulated in the filter, the capacity may decrease

2) R407C capacity is based on dew point conditions

Selection Formulas:

Filter Driers for liquid line are manufactured in compliance with ARI Standard 710. Maximum flow rate of liquid refrigerant at a differential pressure of 0,07bar (1psi) is indicated by kW (ton) which is based on the temperature of liquid refrigerant 30°C (86°F), the evaporating temperature of

-15°C (5°F) and the following mass flow:

• 0,40 kg/min/kW (3.1 lb/min/ton) R134a

• 0,53 kg/min/kW (4.1 lb/min/ton) R404A, R507A

• 0,39 kg/min/kW (3.0 lb/min/ton) R407C

• 0,36 kg/min/kW (2.8 lb/min/ton) R410A

Note: Data on water absorption is based on the following EPD (method: ASHRAE Standard 63.1):

• 50ppm R134a

• 50ppm R404A

• 50ppm R407C

• 50ppm R410A

• 50ppm R507A

English

English 中文

中文

Español

Español Italiano

Italiano Deutsch

Deutsch Français

Français русский

русский Português

Português 한국의

한국의