Features

- High efficient in moisture absorption, filtering impurity, acid, paint remains and mud removal

- Hybrid desiccant

- Solid filter cores are bound with desiccant which can minimize vibration and friction in system operation. And it also reduces the wear of desiccant.

- Filtering fineness: 20?m

- Corrosion resistant painting can survive salt spray test of 500 hours.

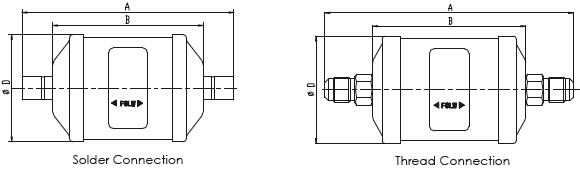

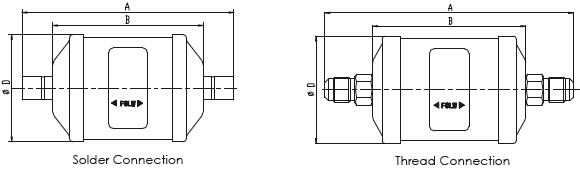

- Connection type: thread or solder

General specifications

- Applicable refrigerant: CFC, HFC, HCFC and HC

- Applicable medium temperature: -30°C ~ 120°C (-22°F ~ +240°F?

- Applicable ambient temperature: -30°C ~ 55°C (-22°F ~ +131°F?

- Maximum working pressure: 4.83MPa (700 pis)

- Certification: UL/CSA

Technical Parameters

| Desiccant Selection Table |

|---|

| Medium | 80% 3A desiccant and 20% active alumina | 100% 3A desiccant |

|---|

| Refrigerant |

HFC |

Applicable |

Applicable |

| HCFC |

Applicable |

Applicable |

| CFC |

Applicable |

Not applicable 1) |

| HC |

Applicable |

Applicable |

| Oil |

Mineral oil or AB |

Applicable |

Applicable |

| Pure POE or PAG |

Applicable |

Applicable |

| POE or PAG with addictive |

Not applicable 2) |

Applicable |

Note:

1) For CFC system, usage of core with alumina is recommended as a strong capability to absorb acid may be needed.

2) When the systems use oil with additive, it is not recommended to use a core with alumina.

STG–05 2(T A)

1 2 3 4 5 |

(1) Product Code |

| STG |

Indicates bi-flow dry filter with solder connection |

| STGL |

Indicates bi-flow dry filter with thread connection |

| (2) Internal volume in3 |

|---|

| 05 |

5 |

| 08 |

8 |

| 16 |

16 |

| 30 |

30 |

| (3) Connection size in |

|---|

| 2 |

1/4 |

| 2.5 |

5/16 |

| 3 |

3/8 |

| 4 |

1/2 |

| 5 |

5/8 |

| 6 |

3/4 |

| 7 |

7/8 |

| 9 |

1-1/8 |

| (4) From of inner core |

|---|

| T |

Solid core |

| (5) Components of inner core |

|---|

| A |

Composed of 80% 3A molecule dessicant and 20% active alumina |

| (Omitted) |

Composed of 100%3A molecule dessicant |

| Model | Connection Size in | D mm | B mm | A mm | Weight g |

|---|

| Solder Connection | Thread Connection | Solder Connection | Thread Connection |

|---|

| STG-052(T)/(TA) |

STGL-052(T)/(TA) |

1/4 |

68 |

76,2 |

113,8 |

109,2 |

450 |

| STG-053(T)/(TA) |

STGL-053(T)/(TA) |

3/8 |

68 |

76,2 |

113,8 |

115,2 |

| STG-054(T)/(TA) |

STGL-054(T)/(TA) |

1/2 |

68 |

76,2 |

124,4 |

120,2 |

| STG-082(T)/(TA) |

STGL-082(T)/(TA) |

1/4 |

68 |

97,3 |

134,9 |

130,3 |

580 |

| STG-082.5(T)/(TA) |

/ |

5/16 |

68 |

97,3 |

134,9 |

/ |

| STG-083(T)/(TA) |

STGL-083(T)/(TA) |

3/8 |

68 |

97,3 |

134,9 |

136,3 |

| STG-084(T)/(TA) |

STGL-084(T)/(TA) |

1/2 |

68 |

97,3 |

145,5 |

141,3 |

| STG-163(T)/(TA) |

STGL-163(T)/(TA) |

3/8 |

80 |

118,1 |

155,7 |

157,1 |

900 |

| STG-164(T)/(TA) |

STGL-164(T)/(TA) |

1/2 |

80 |

118,1 |

166,3 |

162,1 |

| STG-165(T)/(TA) |

STGL-165(T)/(TA) |

5/8 |

80 |

118,1 |

162,1 |

172,1 |

| STG-167(T)/(TA) |

/ |

7/8 |

80 |

118,1 |

178,1 |

/ |

| STG-303(T)/(TA) |

STGL-303(T)/(TA) |

3/8 |

80 |

192,5 |

230,1 |

231,5 |

1700 |

| STG-304(T)/(TA) |

STGL-304(T)/(TA) |

1/2 |

80 |

192,5 |

240,7 |

236,5 |

| STG-305(T)/(TA) |

STGL-305(T)/(TA) |

5/8 |

80 |

192,5 |

236,5 |

246,5 |

| STG-306(T)/(TA) |

STGL-306(T)/(TA) |

3/4 |

80 |

192,5 |

236,5 |

268,9 |

| STG-307(T)/(TA) |

/ |

7/8 |

80 |

192,5 |

252,5 |

/ |

| STG-309(T)/(TA) |

/ |

9/8 |

80 |

192,5 |

262,5 |

/ |

Note: The products listed are standard products which can also be customized.

| Parameters & Capacity List |

|---|

| Model | Flow Rate tons@1 psig?P(tons)1 | Moisture Absorption2 (Drop3) |

|---|

| R134a | R404A

R507 | R22 | R407C | R410A | R134a R507 | R404A | R407C R410A | R22 |

|---|

| 75°F | 125°F | 75°F | 125°F | 75°F | 125°F | 75°F | 125°F |

|---|

| STG-052 |

2,1 |

1,5 |

2,2 |

2,2 |

2,2 |

85 |

79 |

81 |

75 |

74 |

68 |

81 |

74 |

| STGL-052 |

01 |

0,7 |

01 |

01 |

01 |

| STG-053 |

4,7 |

3,3 |

4,8 |

4,7 |

4,8 |

| STGL-053 |

3,3 |

2,3 |

3,3 |

3,4 |

3,4 |

| STG-054 |

7,1 |

05 |

7,2 |

7,1 |

7,2 |

| STGL-054 |

4,5 |

3,2 |

4,6 |

4,5 |

4,6 |

| STG-082 |

2,5 |

1,7 |

2,5 |

2,5 |

2,5 |

195 |

180 |

184 |

171 |

170 |

155 |

184 |

169 |

| STGL-082 |

1,5 |

01 |

1,6 |

1,5 |

1,6 |

| STG-082.5 |

4,5 |

3,1 |

4,6 |

4,5 |

4,6 |

| STG-083 |

4,9 |

3,4 |

05 |

4,9 |

05 |

| STGL-083 |

4,5 |

3,1 |

4,6 |

4,5 |

4,6 |

| STG-084 |

7,3 |

5,1 |

7,5 |

7,4 |

7,5 |

| STGL-084 |

4,7 |

3,3 |

4,8 |

4,8 |

4,9 |

| STG-163 |

5,6 |

3,9 |

5,7 |

5,6 |

5,7 |

352 |

326 |

332 |

310 |

304 |

279 |

332 |

283 |

| STGL-163 |

5,1 |

3,6 |

5,2 |

5,1 |

5,2 |

| STG-164 |

8,6 |

6,1 |

8,8 |

8,7 |

8,8 |

| STGL-164 |

5,6 |

3,9 |

5,7 |

5,6 |

5,7 |

| STG-165 |

9,7 |

6,8 |

9,9 |

9,8 |

10 |

| STGL-165 |

8,6 |

6,1 |

8,8 |

8,7 |

8,8 |

| STG-167 |

12 |

8,5 |

12,2 |

12,1 |

12,3 |

| STG-303 |

7,1 |

05 |

7,2 |

7,1 |

7,3 |

825 |

767 |

778 |

729 |

717 |

657 |

782 |

662 |

| STGL-303 |

06 |

4,2 |

6,1 |

06 |

6,2 |

| STG-304 |

8,8 |

6,2 |

09 |

09 |

9,1 |

| STGL-304 |

7,1 |

05 |

7,2 |

7,1 |

7,3 |

| STG-305 |

10,1 |

7,1 |

10,3 |

10,2 |

10,4 |

| STGL-305 |

8,8 |

6,2 |

09 |

09 |

9,1 |

| STG-306 |

11,26 |

08 |

11,4 |

11,3 |

11,5 |

| STGL-306 |

10,1 |

7,1 |

10,3 |

10,2 |

10,4 |

| STG-307 |

13,2 |

9,2 |

13,4 |

13,3 |

13,5 |

| STG-309 |

15,4 |

10,8 |

15,7 |

15,5 |

15,8 |

Note1? Filter Driers for liquid line are manufactured in compliance with ARI Standard 710. Maximum flow rate of liquid refrigerant at a differential pressure of 1psi is indicated by Ton which is based on the temperature of liquid refrigerant 86°F and the following mass flow:

3.1 lb/min/ton R134a

4.1 lb/min/ton R404A, R507

3.0 lb/min/ton R22, R407C

2.8 lb/min/ton R410A

Note2? Data on water absorption is based on the following EPD (method: ASHRAE Standard 63.1):

60ppm R22

15ppm R12

30ppm R502

50ppm R134a, R404A, R507, R410A, R407C

Note3? 20 drops of water?1g (1cc)

Note: The above data is based on cleaning system of ideal condition; after impurities accumulate in the filter, the flow will decrease.

View all product data

English

English 中文

中文

Español

Español Italiano

Italiano Deutsch

Deutsch Français

Français русский

русский Português

Português 한국의

한국의